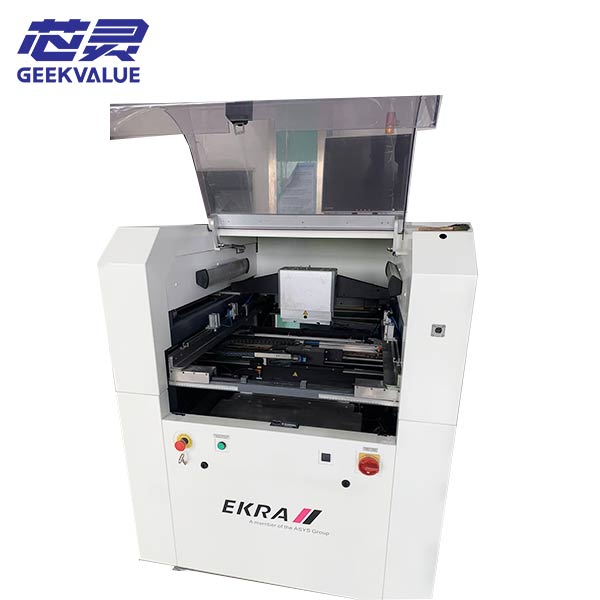

The EKRA E2 is a high-precision automatic screen printer designed for modern SMT assembly lines. It offers exceptional print accuracy, fast cycle times, and long-term reliability. Engineered in Germany, the E2 combines intelligent control technology with a compact design, making it ideal for both prototype and mass production environments.

Whether used for solder paste or adhesive printing, the EKRA E2 delivers consistent results and supports a wide variety of PCB sizes and stencil types.

Main Features of EKRA E2 SMT Printer

1. High Printing Accuracy

The E2 provides printing accuracy up to ±25 µm @ 6 Sigma. Its advanced vision alignment system ensures perfect registration even for fine-pitch components such as 0201 and 01005 packages.

2. Intelligent Vision System

Dual-camera recognition enables automatic board alignment and stencil inspection. The vision system compensates for PCB warpage, ensuring stable printing results for each cycle.

3. Fast Cycle Time

With optimized mechanics and control software, the E2 achieves a print cycle time of less than 10 seconds, helping manufacturers increase throughput and line efficiency.

4. Flexible PCB Handling

Supports single and double-sided PCBs. The adjustable clamping system and vacuum support provide reliable fixation for different board thicknesses and materials.

5. User-Friendly Interface

Equipped with an intuitive touchscreen interface, operators can easily load printing programs, adjust parameters, and monitor production in real time.

6. Robust and Durable Design

Built with EKRA’s proven engineering quality, the E2 offers excellent stability, minimal maintenance requirements, and a long operational lifespan.

EKRA E2 Technical Specifications

| Parameter | Description |

|---|---|

| Model | EKRA E2 |

| Printing Accuracy | ±25 µm @ 6 Sigma |

| Repeatability | ±12.5 µm |

| Max PCB Size | 460 × 400 mm |

| Min PCB Size | 50 × 50 mm |

| PCB Thickness | 0.3 – 6 mm |

| Cycle Time | <10 seconds |

| Printing Area | 420 × 360 mm |

| Stencil Size | 600 × 550 mm |

| Power Supply | 230V, 50/60Hz |

| Machine Weight | Approx. 750 kg |

Specifications may vary depending on configuration.

Typical Applications

The EKRA E2 Screen Printer is suitable for:

SMT assembly lines

Fine-pitch PCB solder paste printing

LED module and display production

Automotive electronics

Consumer electronics

Communication and IoT devices

Its stable performance makes it ideal for high-mix, high-precision manufacturing environments.

Advantages of EKRA E2 Screen Printer

| Advantage | Description |

|---|---|

| Accuracy | Ensures precise solder paste deposition for fine-pitch components. |

| Speed | Optimized motion control achieves fast print cycles. |

| Ease of Use | Simple operation via touchscreen interface. |

| Reliability | German-engineered structure ensures long service life. |

| Flexibility | Compatible with various PCB sizes and stencil frames. |

Maintenance and Service

The EKRA E2 is designed for easy maintenance with modular components and self-diagnostic functions.

Routine care includes:

Regular stencil cleaning and inspection

Vision calibration checks

Conveyor and clamp lubrication

Periodic software updates

Our technical team provides full support for installation, operator training, and spare parts supply to ensure stable production operation.

Frequently Asked Questions

Q1: What makes the EKRA E2 different from other screen printers?

The E2 offers a balance between high precision, compact design, and cost efficiency, making it ideal for small and medium SMT lines without compromising performance.

Q2: Can the EKRA E2 handle fine-pitch components?

Yes. The E2 supports fine-pitch printing for components down to 01005 with its advanced vision alignment system.

Q3: Is the E2 compatible with lead-free solder paste?

Yes. It supports both leaded and lead-free solder pastes and can be configured for various paste viscosities and stencil thicknesses.

Contact Us

Looking for a reliable EKRA E2 Screen Printer for your SMT production line?

GEEKVALUE provides professional sales, calibration, and after-sales support for EKRA screen printers and other SMT equipment.